The background:

It all started from early February 2020, when shocking images went viral online showing thousands of beds being set up inside some makeshift hospitals in order to accommodate thousands of people diagnosed with Noel-Coronavirus in Wuhan China.

the local government initiated an unprecedented disease control campaign by taking inpatient a sheer number of infected cases within large indoor spaces of emergently converted public buildings such as stadium/exhibition centres. However, there had been concerns among some medical professionals that there could be the potential risk of cross-infection among hundreds of patients with different underlying health conditions, along with potential flu virus; on the other hand the on-site medical staff were also exposed to this highly infectious disease in a similar level to, but with less protection than, other acute or CDC specialist hospitals.

the architect attempted to explore mobile architecture offering better individual isolation, by proposing a system of rapid deploying negative-pressurised isolation pods (Iso-Pod), which could be fast and cheap to build, lightweight, moderately sized, transparent to enable group supervision and communication. This article elaborates on the context and evolution of the idea.

Working principles:

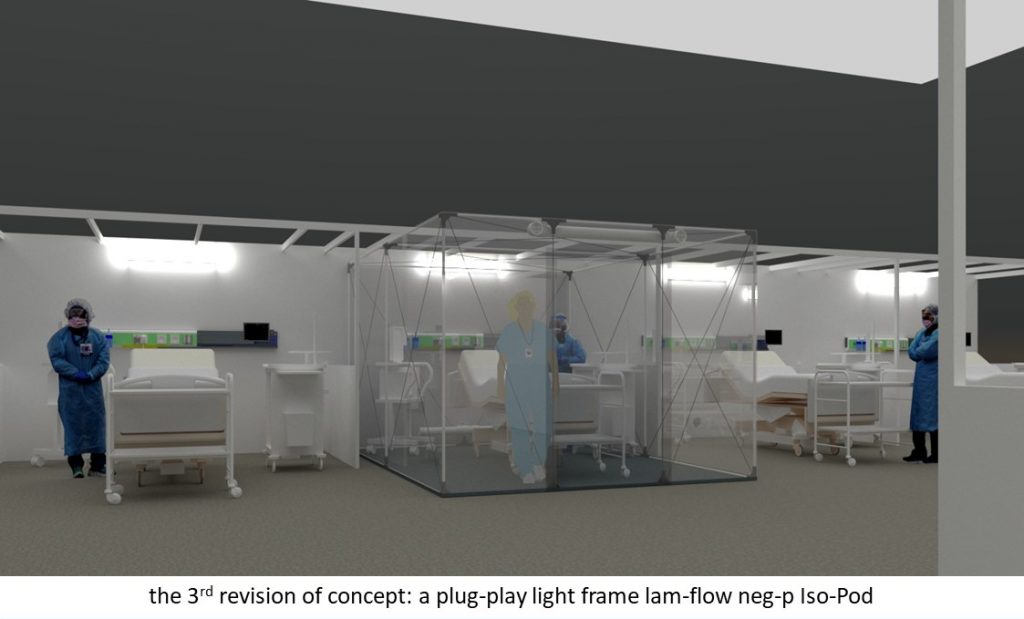

- Operating in a similar principle with a proper airborne infectious disease wards and CBRN tent, a Iso-Pod provides one-way air movement where in-took air flow from higher position (assumed as where the doc/nurse normally stand) within a room towards lower position, normally around the pillow side of the patient bed, and subsequently extract away. There is a constant air pressure difference between inside and outside of the patient room.

- But unlike those precedents, the Iso-Pod is designed as a cheap solution for large scale disaster responding sheltering scheme, where hundreds typically over one thousands infected people could be nursed under one roof.

- Also, unlike CBRN equipment, the basic pack of Iso-Pod is not intended for use in outdoor with unfurnished ground/floor;

- Not designed to provide privacy, rather, it is to offer high level of transparency to enable group supervision, and communication at least visually towards bigger surrounding and outside in a hope to boost the mental health of the inpatients, who may well be staying inside the pods for few weeks even months.

- The initial version concept was focused on its initial context only, that was: aimed for indoor use only, upholding the positive side of pavilion hospital,

- Peripheral benefit: thermal comfort, acoustic barrier, some sense of privacy, for non-acute patients it also allows self-maintaining daily activity.

Use scenarios/user profile

Primarily used for isolating individuals who are suspected having contracted airborne infectious disease eg CoViD-19 from HCP and other people waiting for test/ treatment without or with little respiratory protection.

Mostly likely suitable for:

- To be erected in clusters or single unit as a temporary airborne-disease isolation ward inside a hall of any hospital (in particularly in rural or deprived area) having to accept ABID patient where there was NO such provision before the outbreak and no need to keep such provision afterwards. or when it is not possible to extend its isolation capacity in conventional ways, or

- To be erected, in clusters or single unit inside a makeshift airborne-disease pavilion hospital that housing confirmed mild cases, as treatment rooms where the intensity/concentration of air-borne virus is deemed to be considerably higher than the rest of open area; or

- According to USA CDC guidance, as expedient patient isolation rooms reducing risk to individuals entering the room, or

- converted into a positive-pressurized pod, as staff accommodation within the open area of a makeshift airborne-disease pavilion hospital. Or,

some other potential users:

- To be used inside a stadium-style humanitarian shelter in disastrous period to isolate those airborne-disease infected individuals from rest of the crowd; or,

- As transitional test pods within quarantine zone inside aviation terminals and national/international border control areas, or

- Prison or garrison/barrack without proper CRBN provision, where mass infection could be an imminent threat or potential risk.

Design Strategy

The basics:

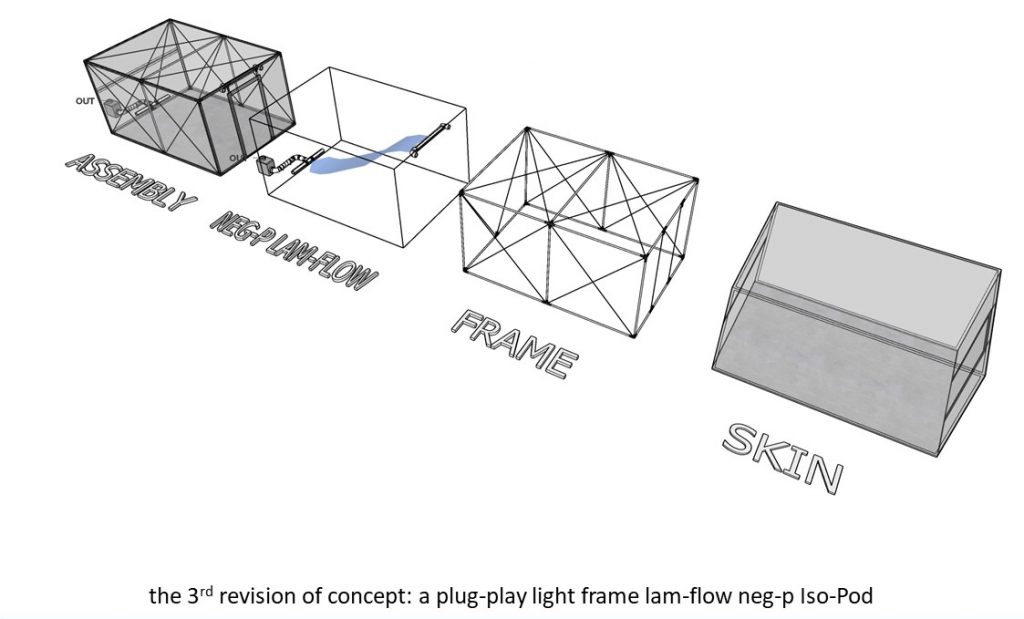

- However small and basic this Iso-Pod might be, it still covers typical architectural concerns , such as Skin, Structure and Services

- prefabricate plug-n-play isolation pod made from a transparent PVC/TPU envelope over a lightweight fast-assembled frame,

- a site-related service system providing negative pressure ventilation and sterilization, and bedhead medical service trunk/outlets

upgrading:

- makeshift ICU provision, add on a pressurized front lobby of similar constructions;

- outdoor provisions, add on secondary shading/rain screen;

- group-up provisions, add on coupling components;

- positive pressure conversions, conditional reversing the HVAC system

- water-supply and drainage provisions, add on flooring/opening components

downgrading:

- reduced dimensions for both envelop and frame, mainly for domestic use, such as Home-based self-isolation or individual isolation from the rest of family where the room has to be shared.

The skin/envelop

- 1-1.5mm flame-retard TPU/PVC films, thermo-wielded into 5~6 facets with possible rubber floor sheet.

- Dimensions: from (2.4~3)W x 3L x 2.2-2.8H(meter), width is related to clinical need around the bedsides, height variable according to roof geometry;

- single access controlled by zipped flap or magnetic closing straps

- Pre-set air-tight fenestrations for ventilation (in/out) and medical-services

- Prefixed ties connect to negative pressure sustaining bracing second to the frame

- Pre-fixed internal ties as hanging provision for future equipment support.

The structure/ frame in two scenarios:

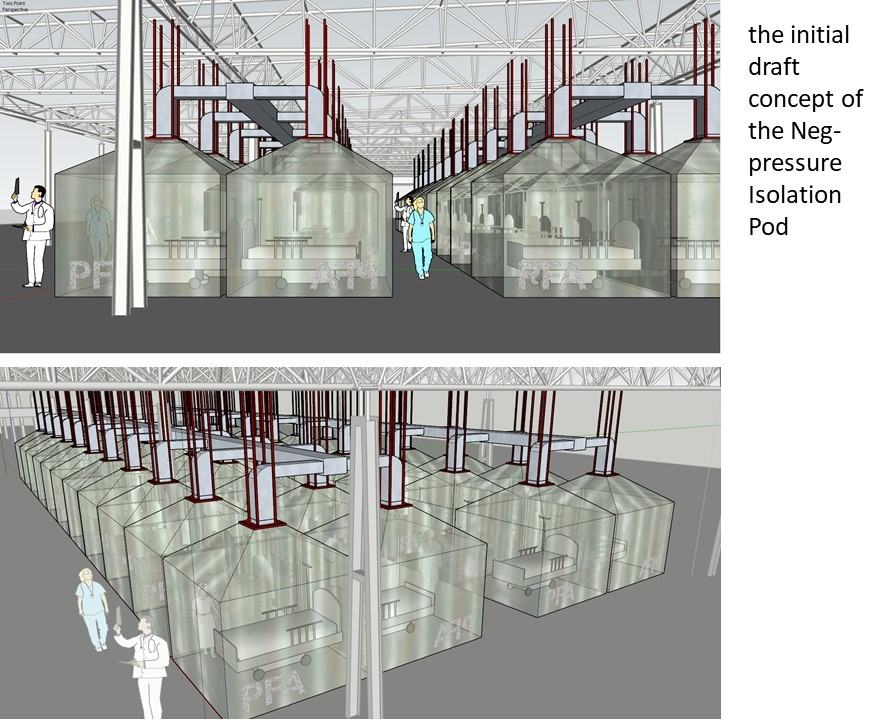

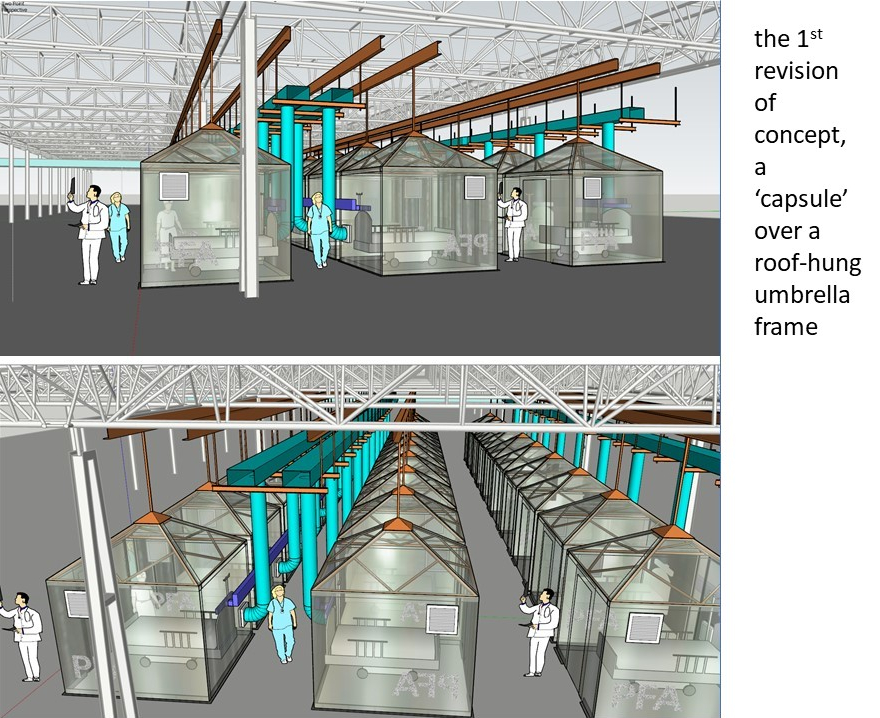

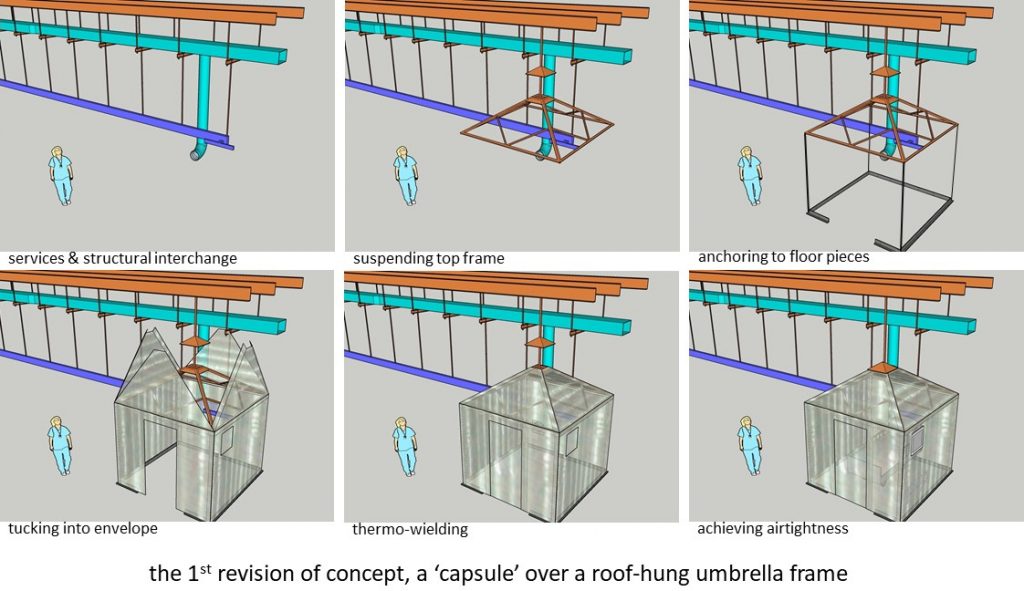

- Initially, to reduce interfering with the already operational hospital to the minimum,suspended umbrella structure was proposed, taking advantage of existing roof truss, possibly with a generic transferring grid.

- Later, to suit more generic site conditions, self-support frame was also discussed to trade off the benefit of having a more self-sustained system and minimum interruption.

- Both systems need secondary bracing for maintaining stability and holding pressure-resistance ties

The services

- Mobile service units, stand-alone solution and cluster solutions are all possible depending on the clinic needs;

- While cluster solution needed, a site-related service system will provide negative pressure ventilation (with or without fresh air supply) and sterilization/disinfection,

- through pre-set air-tightness opening on the envelop, allows optional bedhead trunking/outlets (eg medical gases/power/data/lighting etc) to enter the pod.

Concept evolution

- The original version was worked out very quickly and its basic spatial and material regime remain valid during the following revision, however, the architect soon recognized that it roof level air-extraction needs to be reconfigured to respond to airborne infectious disease.

- 1st revision was made to reorganize the air movement to meet a safer clinic environment.

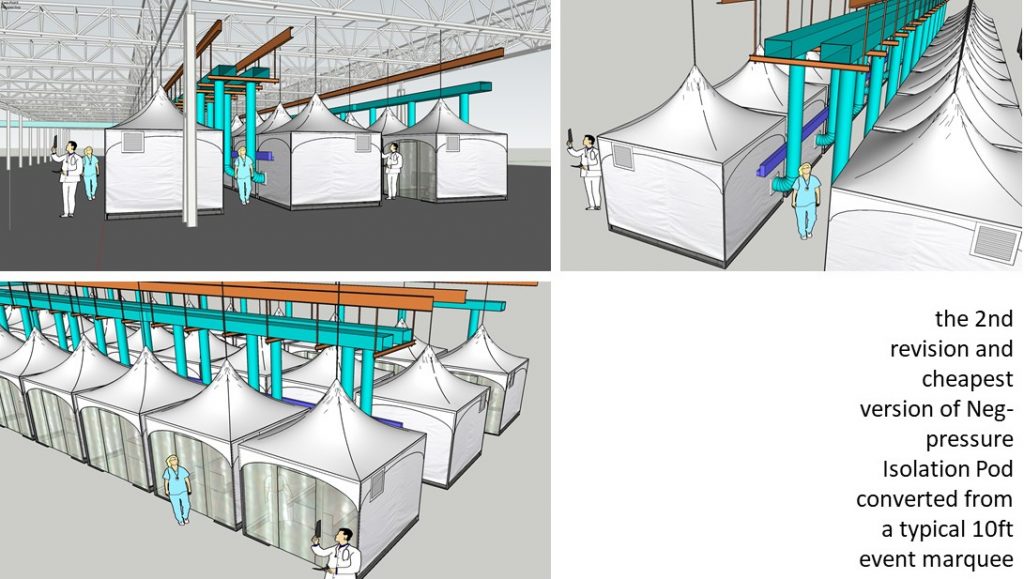

- 2nd revision was an attempted as an emergent response shortening the D&R and manufactory lead stage of structural frames, here the original full transparent envelop was intended to be adapted with a converted 10ft out-of-shelf marquees.

Mass production unit Cost estimated less on-site service preparation

- Transparent version: RMB2000-4000

- Converted version: RMB1500-2000

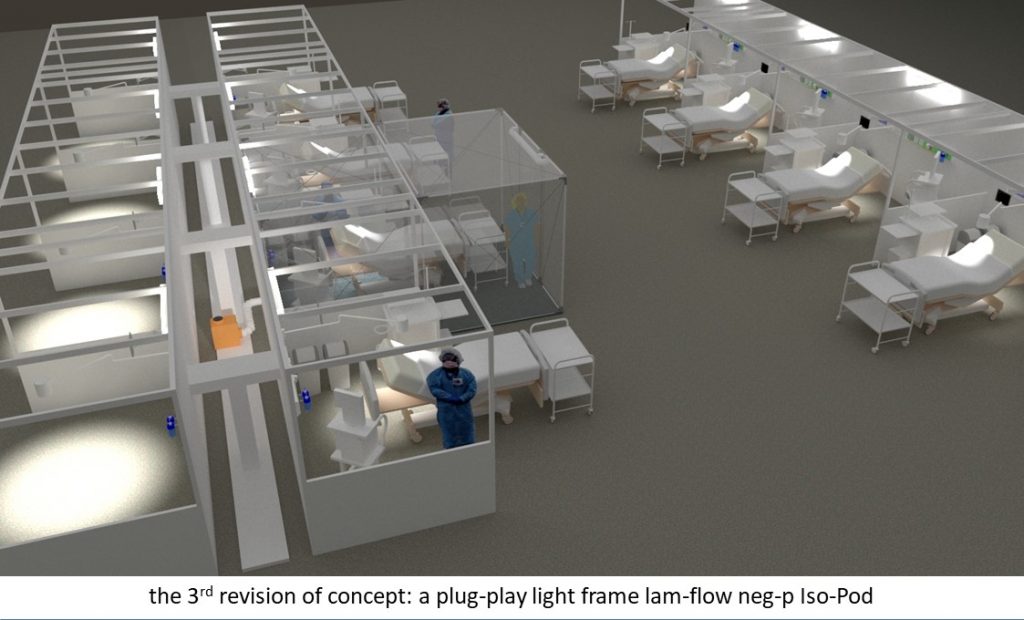

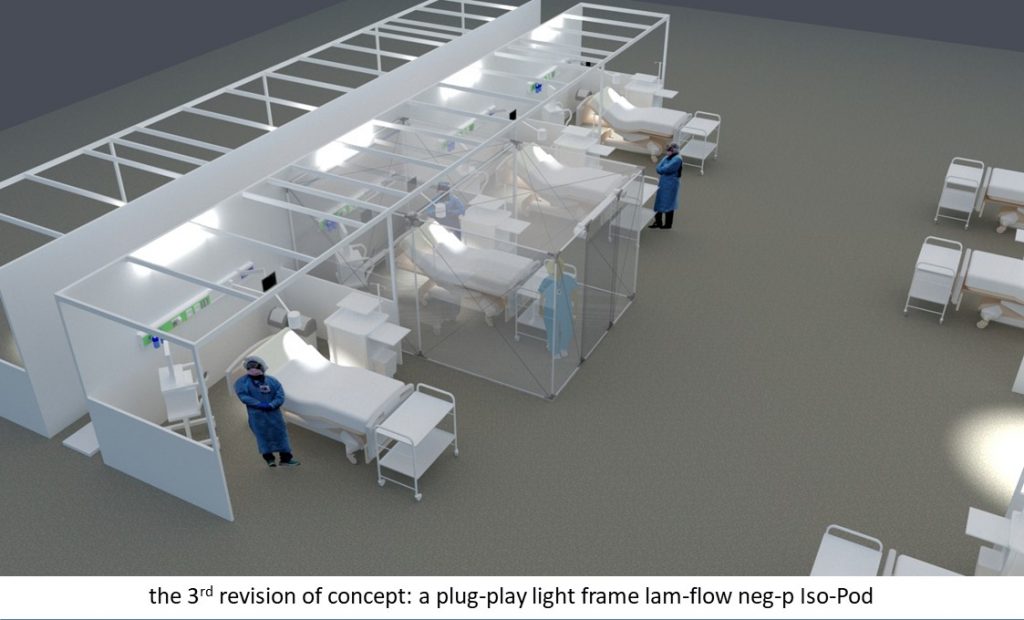

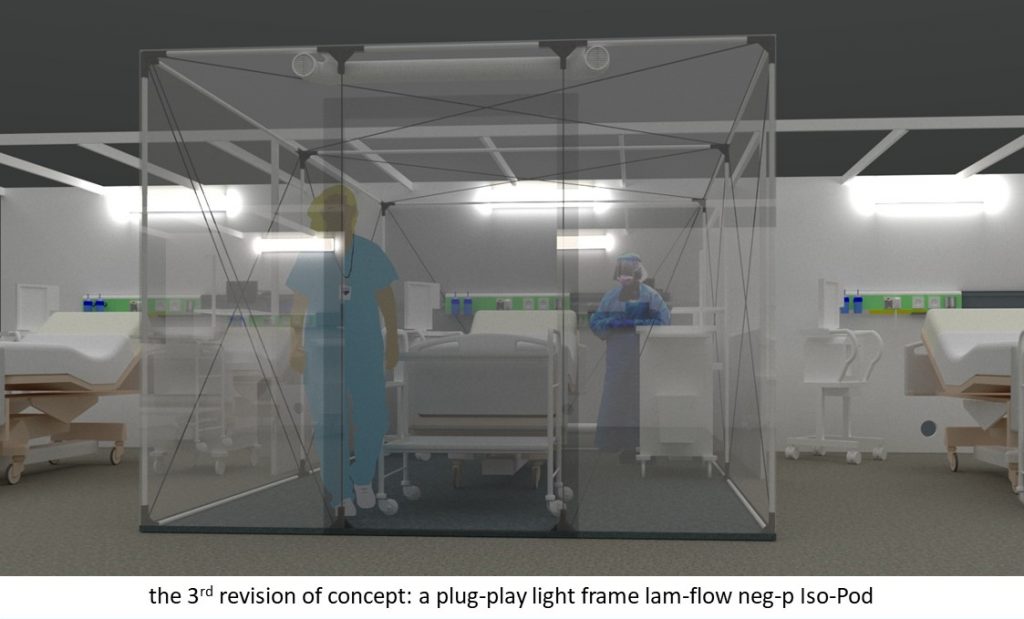

3rd revision of the Iso-Pod, which was based on its original idea, but designed to be an add-on specifically for the makeshift hospitals similar to London Excel or Manchester G-MAX Nightingale Hospital.

Just a couple of months later, the epicenter shifted away from China to Europe, UK, and USA, where some makeshift hospitals were quickly put under construction in similar but upgraded manners to their Chinese counterparts.

NHS Nightingale Hospital London under inital construction (Getty images)

Contractors work at ExCel London NHS Nightingale Hospital ( REUTERS )

However, as opposed to its counterparts in Wuhan, which only housed CoVid-19 patients with mild symptoms, and also unlike its counterparts in NewYork Javitz Connection Centre that only non-CoVid patients being taken care of, the London ExCel Nightingale NHS Hospital was aimed for those infected who need intensive care but have better chances of surviving.

While at this stage it is less worrying for possible cross-infection among the confirmed patients, but it is still worthwhile thinking about the high risk imposed to the HCP/support teams(may still have inadequate PPEs) working inside these open-plan super-Nightingale-ward type of ICU, where the concentration of virus is thought to be higher than those Chinese counterparts. particularly during the resuscitation stage, when the tracheal intubation very often must be performed. Put under an airborne disease context, this could be most dangerous to the on-site HCPs because viruses can travel to a much wider area through aerosol forms than through droplets. Inside a proper ICU ward dedicated to ABD treatment, this could be contained by means of negative pressure isolation ward/rooms that are independently ventilated. But in places like London ExCel, those 2m height partitions seem very unlikely to be able to prevent this type of spreading.

This lightweight low-cost plug-play Neg-pressure Lam-flow Iso-Pod could be produced as mobile units that could be shuffled around the ward, without changing its current regime, and be tucked into any bay where the patient appears creating aerosol spreading. It can then be retrieved and moved to another place when needed. The unit cost as such should be controlled around £1500 or even lower. Not only because it’s cheap to build using simple lightweight alloy/CHS tubes as frames and TPU/PVC film as envelop, but also that the visual contact enabled by its transparency offering high nursing efficiency that is typical of a Nightingale ward, which means lower staffing cost as well.

Quantitative attention had been paid to details to ensure the structural/envelope integrity under negative pressure, to create an envelope engaging with the existing wall-mounted medical outlets and regaining airtightness after installation, to install a cost-saving device delivering single direction airflow enhancing the isolation of air-borne diseases patient.

If being compared with other similar makeshift hospitals in German/USA/Turkey/Iran/Spain etc where roofless partitions had been installed, the London ExCel Nightingale had thankfully made provision for service runs in between two rows of bays at a 1m gap. This enables future negative-pressure sterilizing ventilation to be installed either individually or grouped in clusters via soft vent pipes.